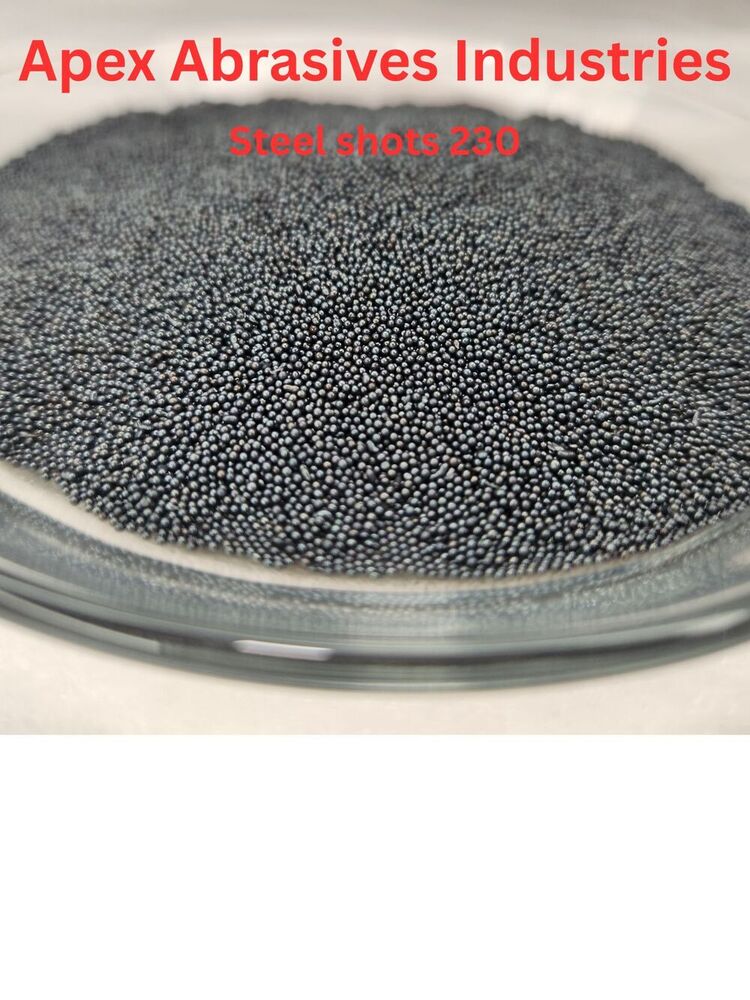

About Steel Shots S-230

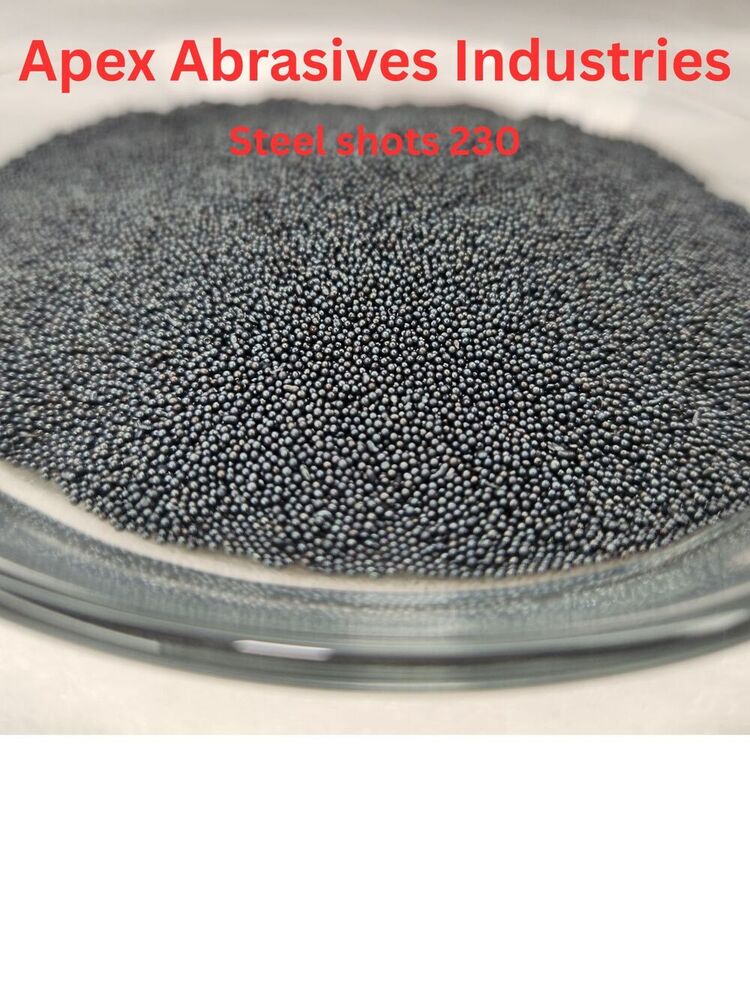

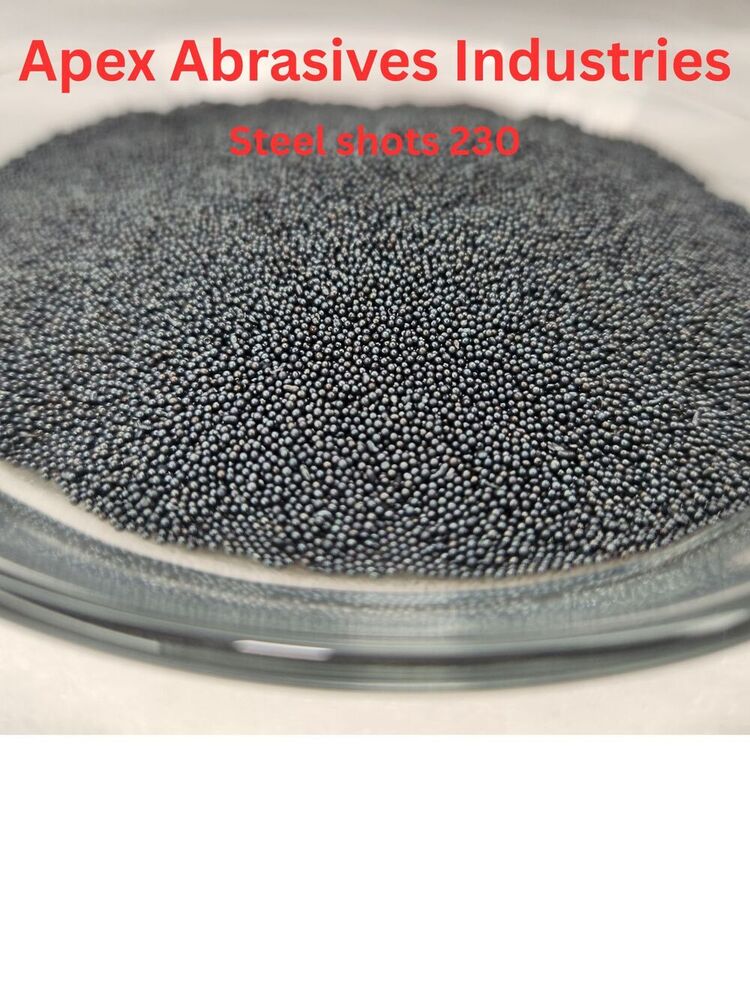

Steel Shot S-230 is a high-performance,spherical abrasive made from premium-grade high-carbon steel. In S-230 shots 230 denotes a nominaldiameter range between 0.6 and 0.7 millimeters. These steel shots are commonlyemployed in various applications, such as cleaning, peening, and descalingsurfaces like metal, concrete, or other materials, making it highly suitable for industries like automotive,aerospace, and metal fabrication.s-230 is Designed to reduce dust productionduring operation, it improving operatorsafety and environmentalcleanliness. It is Easy to collect and separate using magneticsystems, and streamlining post-blasting processes.

Superior Surface PreparationThe Steel Shots S-230 excel in providing thorough surface cleaning and finishing. Their spherical shape ensures even impact during shot blasting, resulting in cleaner and smoother surfaces. This makes them ideal for industries that require robust and consistent outcomes in metal preparation for coating, painting, or fabrication.

Eco-Friendly and Cost-EffectiveCrafted from high carbon steel, the S-230 shots are not only durable but also recyclable. Their recyclability helps reduce operational costs and supports sustainable practices. Industries benefit from repeated use without compromising the quality of the blasting process, contributing to both efficiency and environmental responsibility.

FAQs of Steel Shots S-230:

Q: What are the main benefits of using Steel Shots S-230 in shot blasting applications?

A: Steel Shots S-230 offer excellent surface cleaning, consistent results due to their uniform spherical shape, and remarkable durability thanks to their high carbon composition. Their recyclability also contributes to cost savings and sustainability in industrial processes.

Q: How are Steel Shots S-230 used in industrial shot blasting?

A: These steel balls are loaded into shot blasting machines where they are propelled at high energy to remove contaminants, rust, and paint, or to create a specific surface texture. Their hardness and uniform size help deliver effective and predictable finishing outcomes.

Q: When should you choose Steel Shots S-230 over other abrasive materials?

A: Steel Shots S-230 are ideal when a recyclable, high-performance abrasive is needed for demanding applications. Their use is recommended when consistent surface coverage and minimal residue are required, as in preparing metals for coatings or welding.

Q: Where can Steel Shots S-230 be sourced in India?

A: Steel Shots S-230 are supplied by various dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India, ensuring accessibility for both small-scale and large-scale industrial buyers.

Q: What is the process for recycling Steel Shots S-230 during shot blasting operations?

A: Recycling involves collecting used shots, cleaning and removing any contaminants or broken particles, and then reintroducing them into the blasting cycle. This process maintains blasting efficiency and reduces waste generation.

Q: How does the high carbon content affect the performance of Steel Shots S-230?

A: The elevated carbon level enhances hardness and durability, allowing the shots to withstand repeated impacts during blasting. This ensures longevity, reduces replacement frequency, and supports consistent abrasive action on surfaces.