About Steel Shots S-280

Steel shot size S-280 refers to aspecific classification of abrasive particles used in shot blastingapplications. The "S stands for steel, and the number "280 denotes thenominal diameter of the shot is 0.07 mm. Steel Shot S-280 combines efficiency,longevity, and performance, offering a cost-effective solutionfor industries that demand high-quality surface preparation with controlledresults. Whether used in wheel blast machines or air blasting systems, S-280provides consistent, repeatable performance.

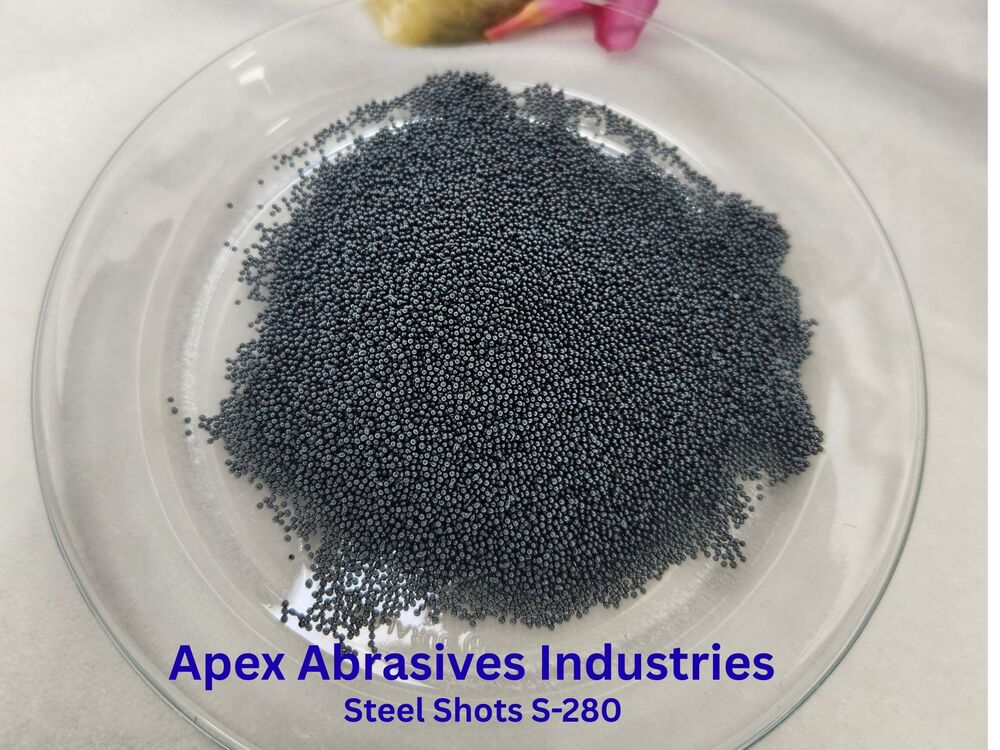

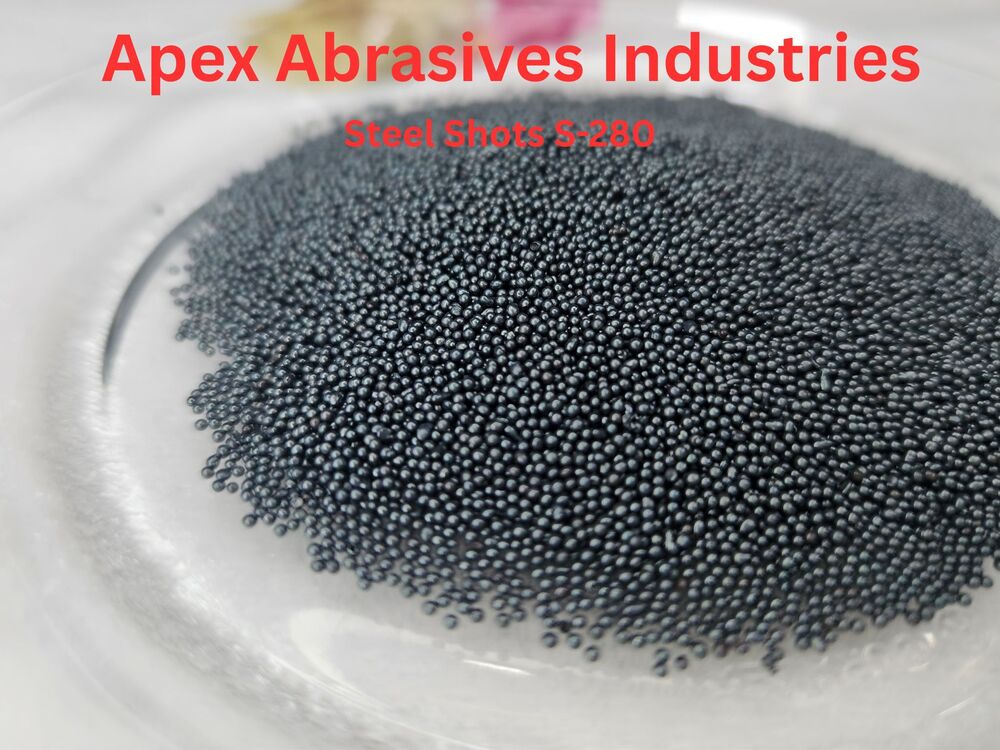

Premium Quality Steel Shots for Shot BlastingS-280 Steel Shots, made from high-grade carbon steel, are precisely shaped into balls with a 0.7mm thickness. Their superior hardness and consistent size ensure efficient shot blasting, providing thorough surface cleaning and preparation. These steel shots are recyclable, delivering continued cost savings for industries seeking durability and performance. Sourced from leading suppliers in India, S-280 shots are suitable for various industrial needs including automotive, construction, and metal fabrication.

Material Composition Enhances PerformanceCarefully balanced material composition provides optimal toughness for intensive blasting tasks. With 0.85-1.20% carbon, 0.45-1.50% silicon, and 0.35-1.20% manganese, plus minimal phosphorus and sulphur, these steel shots combine strength and longevity. Their metallic grey color and spherical shape facilitate uniform blasting, decreasing wear and increasing reliability throughout extended use cycles.

FAQs of Steel Shots S-280:

Q: How are Steel Shots S-280 used in shot blasting processes?

A: Steel Shots S-280 are propelled at high velocities by blasting machinery to clean, strip, and prepare metal surfaces for further finishing. Their spherical shape and consistent hardness make them ideal for removing rust, scale, or old coatings efficiently.

Q: What benefits do Steel Shots S-280 offer over other abrasives?

A: Steel Shots S-280 deliver excellent durability due to their high carbon composition and hardness. They are recyclable, ensuring multiple uses, and produce a uniform surface profile ideal for subsequent coating applications.

Q: When is it recommended to use S-280 grade steel shots?

A: S-280 steel shots are recommended for applications requiring medium-level surface preparation, such as automotive parts cleaning, metal fabrication, and construction where controlled blasting intensity is necessary.

Q: Where can I source Steel Shots S-280 in India?

A: Steel Shots S-280 are available through dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers across India, ensuring convenient procurement for businesses nationwide.

Q: What is the manufacturing process for Steel Shots S-280?

A: S-280 steel shots are produced by melting high carbon steel, atomizing it into spherical particles, then heat treating and screening them for hardness (40-50HRC) and precise size (0.7mm thickness) before packaging.

Q: Can Steel Shots S-280 be recycled after use?

A: Yes, these steel shots are recyclable. Their durability promotes repeated usage in shot blasting cycles, which helps reduce operational costs and supports environmentally responsible manufacturing practices.

Q: What are the key material properties of Steel Shots S-280?

A: S-280 shots contain 0.85-1.20% carbon, 0.45-1.50% silicon, and 0.35-1.20% manganese, with phosphorus and sulphur levels kept below 0.05%. These properties contribute to the shots strength, wear resistance, and consistent blasting results.