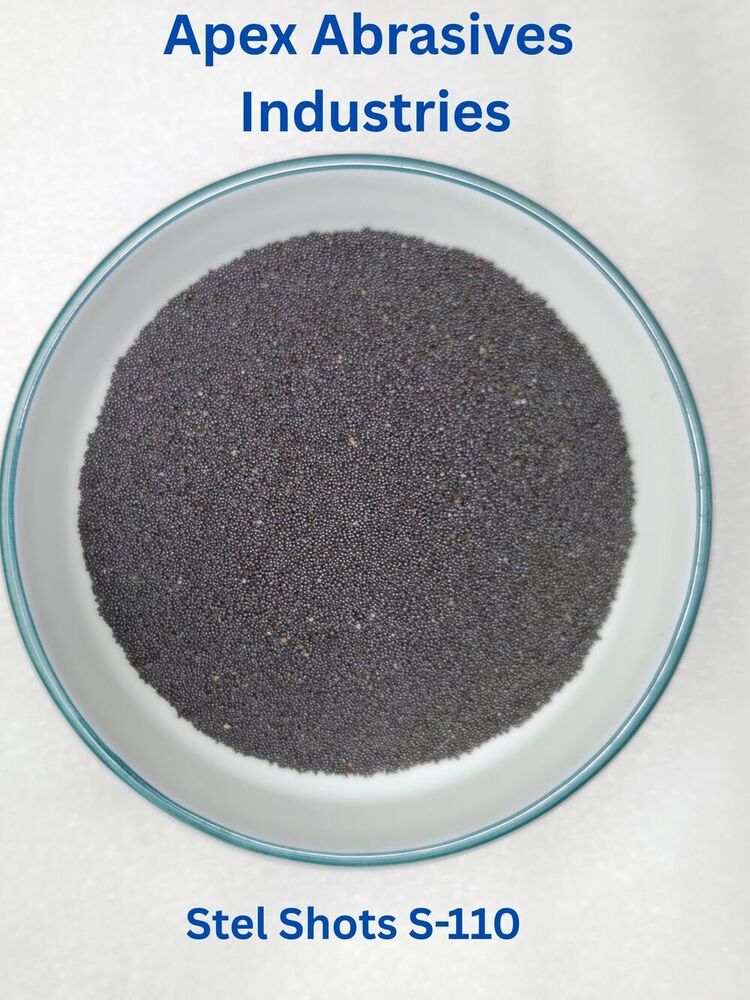

About Steel Shots S-110

The "S stands for steel, indicating the material composition, while the number "110 denotes the mesh size. In this context,S-110 steel shots have a particle size distribution that corresponds to the 110mesh size, Shot S-110 is a fine, spherical abrasive made from high-carbon steel, engineered for precision surface treatment. With a nominal diameter of 0.3 mm, S-110 is ideal for applications requiring controlled cleaning, like Cleaning thin-walled casting sand precision components ,Removing sand, oxides, and residues from delicate molds, cleaning engine parts, crankshafts, cylinder heads, and gears etc. Its smaller particle size allows it to reach narrow spaces and deliver aconsistent, uniform finish on delicate or intricately shaped parts. Commonly used in automotive, aerospace, and precision casting industries, S-110 offers excellent coverage and recyclability.

Advanced High Carbon CompositionThe Steel Shots S-110 are engineered with a high carbon formula, combining durability and efficiency. Their composition not only enhances resistance to wear but also ensures consistent performance in abrasive environments. This makes them ideal for demanding industrial processes where precision and reliability are essential.

Versatility in ApplicationThese steel shots are perfect for surface cleaning, shot blasting, peening, and other metal treatment processes. Their uniform shape and size enable even results, reducing the risk of surface imperfections and optimizing operational cycles for manufacturers, traders, and end users alike.

Eco-Friendly and RecyclableSteel Shots S-110 are fully recyclable, allowing users to minimize waste and environmental impact. Their robust physical properties further support multiple reuses, contributing to cost savings and sustainability in many industrial applications throughout India.

FAQs of Steel Shots S-110:

Q: How are Steel Shots S-110 typically used in industrial applications?

A: Steel Shots S-110 are predominantly utilized for surface preparation, shot blasting, and peening tasks. Their spherical shape and consistent size provide uniform treatment, ensuring surfaces are cleaned, strengthened, or finished to desired specifications efficiently.

Q: What benefits does the high carbon content provide in Steel Shots S-110?

A: The elevated carbon content in these steel shots increases hardness and durability, enabling them to withstand rigorous abrasive environments. This results in superior longevity and consistent performance across multiple cycles of use.

Q: When should Steel Shots S-110 be chosen over other blasting media?

A: Select Steel Shots S-110 for applications requiring precision, high repeatability, and minimal contaminant introduction. Their hardness and uniformity make them ideal for projects needing reliable, high-quality surface treatment results.

Q: Where can customers source Steel Shots S-110 in India?

A: These steel shots are available through a wide network of dealers, distributors, exporters, manufacturers, retailers, suppliers, traders, and wholesalers throughout India, offering accessibility for various industrial requirements.

Q: What is the process of recycling Steel Shots S-110 after use?

A: After initial usage, spent steel shots can be collected, cleaned, and sorted for reuse. Their high-grade carbon steel composition allows for multiple recycling cycles, minimizing waste and promoting cost-effective operation.

Q: Can Steel Shots S-110 be used with all standard shot blasting equipment?

A: Yes, their standardized 0.3mm size and hardness ensure compatibility with most conventional shot blasting machines, making integration into existing processes straightforward and reliable.

Q: What advantages do Steel Shots S-110 offer compared to non-metallic abrasives?

A: Steel Shots S-110 deliver greater durability, recyclability, and consistency, allowing for extended use and lower operational costs. Their high carbon construction leads to more efficient material removal and surface improvement compared to many non-metallic options.